3D printing constructions are much older than you think. In 1939, the first “wall-building machine” was created by inventor William E. Urschel.

It worked with a system that automatically squeezed and compacted the concrete pressing it between rotating discs, joining each layer as the material was ejected. This laid the foundations for what we know today as additive manufacturing.

How does a 3D Concrete Printer build a home?

It works by “stacking” layers of the material on top of each other, building the structure without molds, like assembling a chocolate bar, but with greater precision.

This precision reduces costs, optimizes the use of materials, generates no direct waste, and requires less labor.

From vision to reality

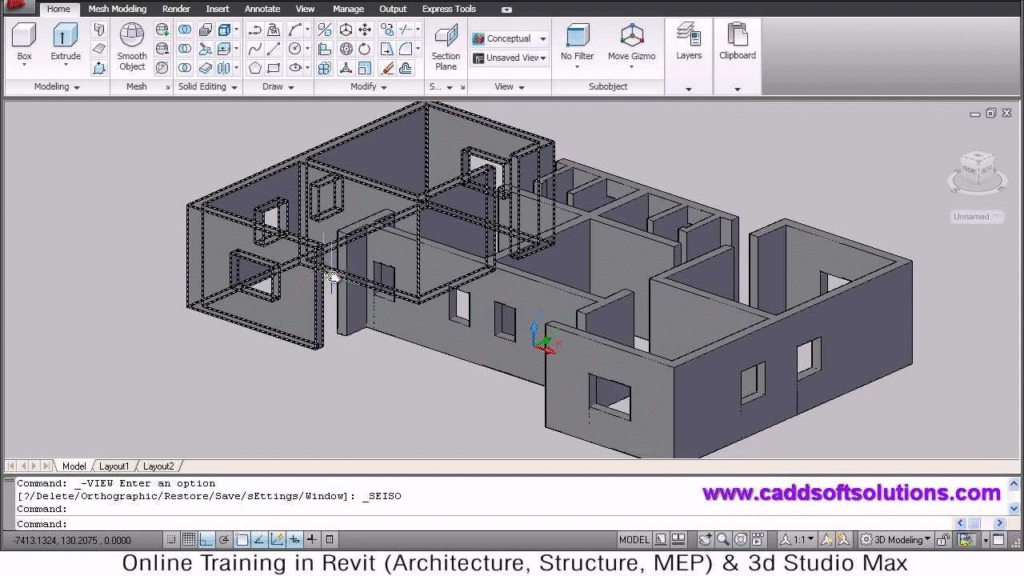

1. Design:

First, a digital 3D model of the building, or CAD (Computer-Aided Design) model, is created. And yes, that’s where the well-known name AutoCAD comes from.

2. Slicing (Cutting in layers):

Once the design is ready, it is divided into horizontal layers through a process called “slicing.” Each of these layers is an instruction on where and how much material to place. Like a cake that has layers.

3. Printing

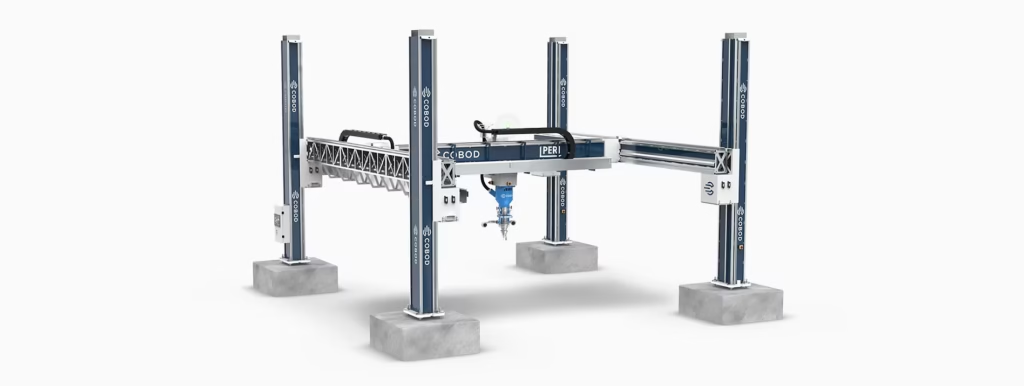

At this stage, the 3D concrete printer deposits the material layer by layer, guided by the instructions in the slicing file. There are two main systems: a gantry system, ideal for large buildings, with a fixed structure to cover large areas, and a more versatile and compact robotic arm system, perfect for small projects or projects with complex geometries.

Gantry system:

Robotic arm:

4. Curing or Hardening:

Once all the layers are finished, a manual curing process is carried out to ensure the strength and stability of the structure.

While this step is essential for concrete, some experimental projects with other materials explore different methods for achieving strength.

5. Finish:

This phase is the same as traditional construction: surfaces are smoothed, windows and doors are installed, and other architectural details are added to make the house habitable.

Conclusion

This technology streamlines the construction process and reduces material waste and costs. However, it still has some limitations, such as project size and specialized professionals.

In addition, the initial investment is high. If you want to know the actual costs compared to other construction techniques, check out our post (link).

And remember, although 3D concrete printer revolutionizing the construction of new structures, concrete cutting is still essential for jobs like remodeling or restoration. In these cases, our cutting-edge technology offers precision, speed, and impeccable results.

Trust the experts at Helder’s Concrete Cutting Company and call us today.